GREENID CO

Unit 5, No.5,Sharifi St.,Behnam St.,

Kashani Blvd, Tehran , Iran

©Copyright by GREENID

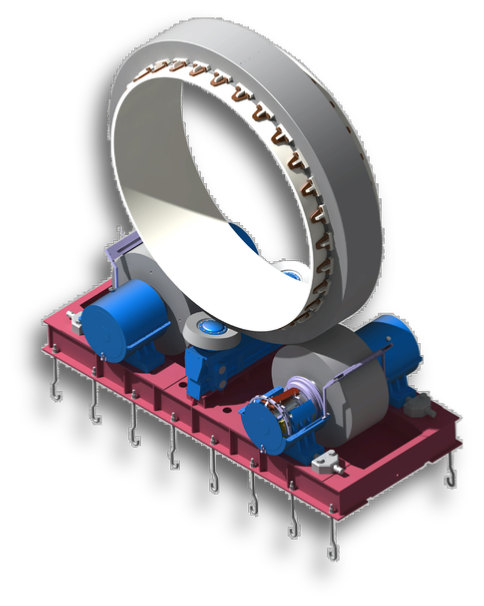

Roller & Tire

The forged rollers and cast tires have solid rectangular profiles. They are manufactured without relief or drilled holes to ensure that no notch stresses or stress concentrations occur. One special feature is the constraint free and low maintenance tire fastening system, which reliably transmits all loads via large contact surfaces at low surface pressure from the kiln shell to the tire. This connection also maintains a perfect contact pattern between the tire and rollers.

They are dimensioned to ensure they are not affected by any types of load resulting from various operating conditions. However, in the event that it is necessary to straight en a bent shell of a three-station kiln during operation, the system is equipped to do so. The extremely robust and solid construction of the bearing arrangement, with double slide bearing blocks which remain aligned, is designed to ensure that the roller stations have a centering effect on the kiln.

They absorb the reestablishing forces of the distorted kiln and do not deflect as flexible or moving bearings would. The axial forces are also effectively controlled and do not result in indefinable changes to the ratio of forces.This controlled absorption of he axial forces is easy to recognize at all times. It helps to precisely adjust the bearing position and to make any necessary corrections during operation. One special advantage is that it offers the opportunity, in the event of changed linear expansion of the kiln shell, to return the roller to an optimal position in relation to the tire by way of the linear adjustment of the bearing block.

No fear of contact

In order to ensure uniform use of the contact surfaces between tires and supporting rollers, as well as the girth gear and pinion, the axial motion of the rotary kiln is hydraulically controlled. The hydraulic thrust roller mechanism counteracts the forces which are generated by the slope of the kiln. It operates automatically and is controlled by non-contact measurement.